Automatic folder gluer stitcher machine

XT- full-automatic folder gluer stitcher machine, by the vacuum paper feeding part, adhesive folding part, nail box part and counting and stacking output part of 4 parts.

Views:

1000

Category

Keywords

Details

Automatic folder gluer stitcher machine configuration

Purpose and characteristics

XT- full-automatic folder gluer stitcher machine, by the vacuum paper feeding part, adhesive folding part, nail box part and counting and stacking output part of 4 parts.

All motors are Taiwan CPG Motors, with the exception of frequency conversion motors. Frequency control, Standard PLC touch screen control (Double PLC, double touch screen) The whole machine electric adjustment, just enter three data on the touch screen (length, width, height dimensions) , the machine automatically adjusted in place.Operation is simple and reliable, nail box and glue box can be independently controlled, glue box highest speed 180m/min, average glue box speed 150m/min, Nail Box 4 nails 70pcs/min. High-speed energy saving, saving labor costs.

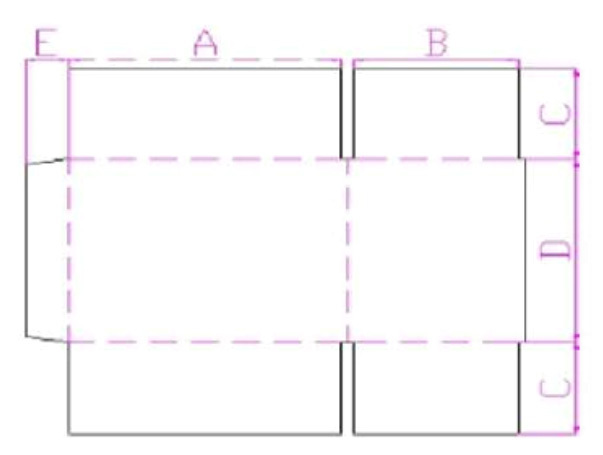

Main technical parameters

|

Model |

XT1226 |

|

|

|

Glue box |

Nail Box |

|

Max paper size(A+B)*2(mm) |

2600 |

|

|

Min paper size(A+B)*2(mm) |

420 |

900 |

|

Max Carton length Amm |

900 |

|

|

Min Carton length Amm |

130 |

270 |

|

Max carton width Bmm |

650 |

|

|

Min carton width Bmm |

80 |

180 |

|

Max paper height(C+D+C)(mm) |

1200 |

|

|

Min paper height(C+D+C)(mm) |

170 |

300 |

|

Max rocker cap sizeC(mm) |

350 |

|

|

Min rocker cap sizeC(mm) |

50 |

|

|

Min height D(mm) |

100 |

|

Main structure

Paper feeding Department:

Air suction feed can better adapt to bending paperboard, frequency control, so that the feed can be controlled alone, easy and reliable operation, stainless steel rubber wheel, corrosion resistance, wear resistance, glue uniform, saving glue, the amount of glue used is about one third of the amount of artificial coating.

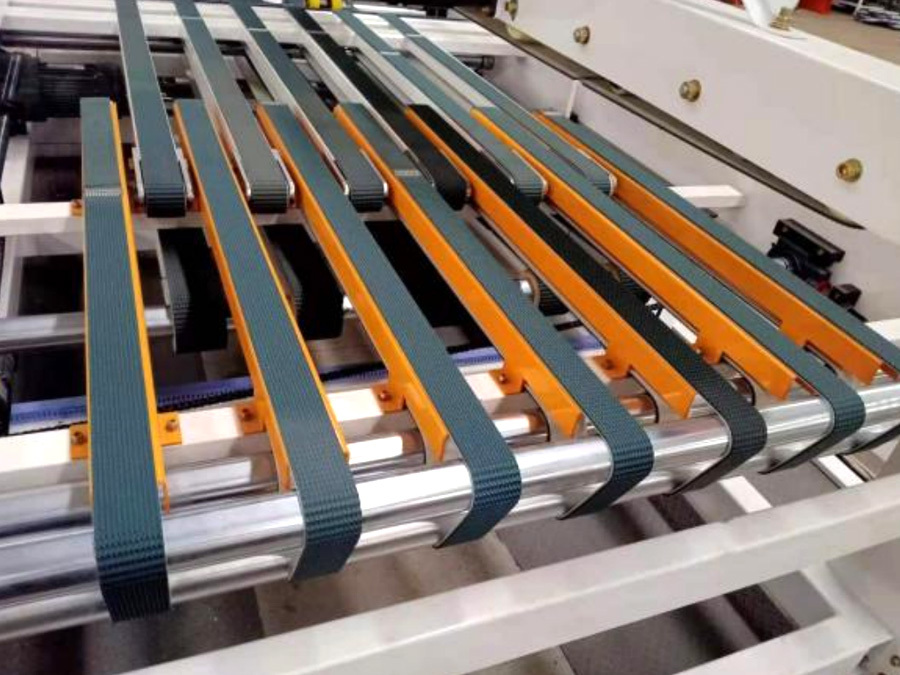

Glue folding section:

Imported wear-resistant rubber belt conveys paperboard for longer use; paperboard rectifying device and creasing device, the creasing wheel is adjustable, suitable for paperboard thickness 2 ~ 8mm; secondary creasing mechanism, second indentation of poor quality of paperboard indentation.

Nail Box section:

Can be independently controlled, nail head automatic lifting, no need to remove any parts, free conversion sticky box and nail box function, a key adjustment, simple and fast operation. Three servo control, using mechanical hand-push paper structure (front and back) , paperboard molding more accurate.

Counting and stacking output section:

1. The principle of counting and stacking is simple and reliable, and the whole stacking part is electrically moved horizontally to ensure the stable output of the large offset carton.

2. All-round electric adjustment of paper feeding belt, simple operation and convenient use.

3. Adjust the baffle button to change the order, automatic adjustment. It has the function of correcting deviation, and the deviation can be adjusted. The counting ejector adopts pneumatic method, and the action is accurate and fast.

4.The double belt drive of the output part can work with any packer, and the application scope is more extensive.

Automatic folder gluer and stitcher inline machine and electrical control section

According to European standard, the whole machine is designed and produced according to the idea of safe and reliable work, convenient operation and maintenance.Color touch human-machine interface and Siemens PLC control (double touch screen, Double PLC) , easy to operate, strong humanization, touch human-machine interface and Master PLC are reserved program upgrade interface, facilitate the future use of equipment upgrades.The whole machine main power motor frequency conversion speed, the use of Siemens brand inverter, speed stability, environmental protection and energy saving (about 30% power saving) , and full protection of the motor (when the voltage is too high or too low, when the motor is too hot or current is too large, the inverter automatically alarm and stop action, there are corresponding alarm code shown) .Siemens AC contactors are used in all contactors used to control the motor, and thermal overload relays are installed to protect the motor when the motor is overloaded. All parts of the machine are connected with wires are connected by aviation plug-in, easy to disassemble and maintain.There are operation buttons installed in both front and back of the machine. The main functions can be operated in both front and back of the machine, and the Operation Button panel is made of stainless steel plate, which is beautiful and generous, the panel uses graphics and text to illustrate the button039;s easy-to-use function, easy to understand.

The main electrical components of the machine using the brand as follows:

|

|

Name |

Brand |

|

1 |

Touch screen |

Siemens |

|

2 |

PLC |

Siemens |

|

3 |

Frequency converter |

Siemens |

|

4 |

Intermediate relay |

Siemens |

|

5 |

Photoelectric switch |

Otonix |

|

6 |

Proximity Switch |

Otonix |

|

7 |

Switching power supply |

Ming Wei, Taiwan |

|

8 |

Thermal overload relay |

Siemens |

|

9 |

Circuit Breakers |

Siemens |

|

10 |

Protector |

Siemens |

|

11 |

Trip switch |

Omron |

|

12 |

Contactor |

Siemens |

|

13 |

Button switch |

Schneider |

Number of workers employed: 2-4.

Fully automatic three-part external dimensions

Paper feeding section:length 1800mm width 3400mm height 1700mm weight 1.5 Tons

Folding part:length 6000mm width 1900mm height 1750mm weight 2.5 Tons

Nail Box section:length 1800mm width 2900mm height 1700mm weight 1.5 Tons

Stacking section:length 4000mm width 2200mm height 1650mm weight 3.5 Tons

The main motor parts of the machine using the brand as follows:

|

Name |

Brand |

|

1.Decelerating motor |

Lee Ming, Taiwan |

|

2.Frequency conversion motor |

Qufu,Shandong Province |

|

3.Fan |

Hebei |

|

4.Servo motor |

Mitsubishi Motors |

Complete Machine Main belt into a piece using the brand as follows:

|

Name |

Brand |

|

1.Front paper belt |

Siegling |

|

2.Synchronous belt |

Mori, Germany |

|

3.Both sides of the belt |

Siegling |

The main bearing parts of the machine use the brand as follows:

|

Name |

Brand |

|

Bearing with housing |

FujianFK |

Previous:

Next:

INQUIRY