XT-F Model flexo printer inline machine

Parameter/Model:XT-F-1224FFG; Max. Sheet Size (F x A):1200x2400mm; Skip Feed Size (F x A):1450x2400mm; Min. Sheet Size (F x A):320x800mm

Views:

1000

Category

Keywords

Details

Attachment:Illustration of machine units

Product Details: Flexo Folder Gluer

Main Technical parameters

|

Parameter/Model |

XT-F-1224FFG |

|

|

Max. Sheet Size (F x A) |

1200x2400mm |

|

|

Skip Feed Size (F x A) |

1450x2400mm |

|

|

Min. Sheet Size (F x A) |

320x800mm |

|

|

Max. Printing Area (F x A) |

1200x2400mm |

|

|

Top Speed |

400 (sheet/min) |

|

|

Economic Speed |

120-220 (sheet/min) |

|

|

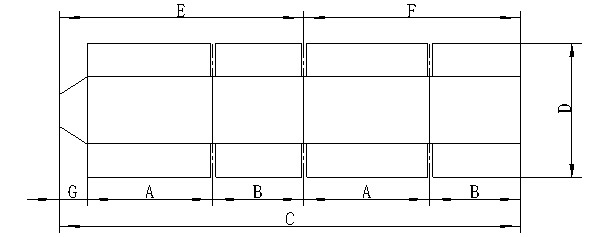

Min. Slotting Space-Reverse Knife (B x C x B x C) |

250x130x250x130mm |

|

|

Min. Size (B+C) |

400mm |

|

|

Max. Slot Depth Size |

300mm |

|

|

Min. Box Height Size (E) |

110mm |

|

|

Max. Die-Cutting Area (F x A) |

1200x2400mm |

|

|

Sheet Thickness |

1.5-11mm |

|

|

Glue side(D) |

≤40mm |

|

|

Thickness of Printing Plate |

7.2mm |

|

|

Total Power |

Flexo slotter die cutter |

120kw |

|

Inline Folder Gluer |

52kw |

|

|

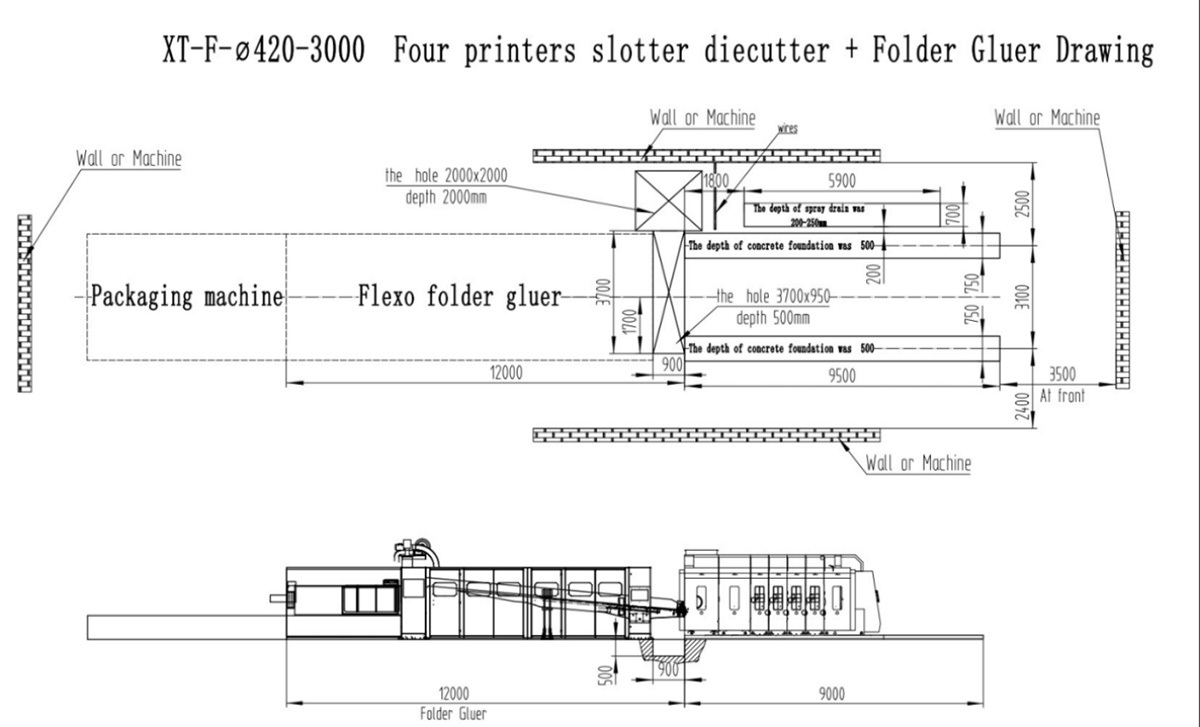

Dimension |

Flexo slotter die cutter |

9000x5350x2650mm |

|

Inline Folder Gluer |

12100x4671x3200mm |

|

CENTRAL COMPUTER CONTROL SYSTEM

|

NO |

Position Design |

Description |

Remark |

|

1 |

HIM |

Integrated computer communicates with each section. |

|

|

Order setting up, save and recall |

|

||

|

Order number input, such as ABC123, max order quantity 3000 |

|

||

|

Date calibration/correction. |

|

||

|

Alarm tele-communication fault and reset. |

|

||

|

2 |

Functional buttons |

Manually control with buttons available. |

|

|

3 |

Remote controller |

Remote control to debug the failures |

|

Feeding Unit

OPTION F1: NON-CRUSH LEAD EDGE FEEDER WITH SERVO MOTOR

|

NO |

Position Design |

Description |

Remark |

|

1 |

Feed mode |

4 sets of servo-motors in order to achieve non-crush results. |

|

|

Extended vacuum transfer table. |

|

||

|

Continue feed/Single feed/Skip feed |

|

||

|

2 |

Air suction |

Suction intensity controlled by inverter |

|

|

Air volume adjustable to suit different size sheets |

By manual |

||

|

3 |

Side guide |

Computerized setting, position with memory storage |

|

|

Automatic side-squarer plate |

|

||

|

4 |

Front guide |

Descending/ascending by motorized |

option |

|

Left/right moving by motorized |

|

||

|

5 |

Back stop |

Forward/backward by motorized |

|

|

Descending/ascending by motorized |

|

||

|

6 |

Dust removal system |

2 sets of dust blower with 3 rollers , 2 rows with xerocoty brusher. |

|

|

7 |

Paper guide roll |

1 pair of guide roll |

|

|

Bottom roll is equipped with 3 pcs of guide rings. down roll is made of steel roll. Top roller is made by PU roll. |

|

||

|

The pressure adjustable by computerized, Range 0-11MM |

|

||

|

8 |

Gear lubrication |

Oil circuit balancer to connect each section. |

|

|

One lubrication oil pump for gear |

|

||

|

9 |

Main motor |

Frequency inverter control |

|

|

Delay-start safety protection |

|

||

|

The machine cannot start when it is unlocked |

|

||

|

10 |

Alarm buzzer |

It sounds when units opening and closing,and improper operation |

|

|

11 |

Auto zero function |

Zero position return |

|

|

12 |

Auto adjustment sheet gap |

When changed order with different thickness sheet into above photo to measure the sheet thickness, whole machine roll gap will be automatic adjustment |

|

OPTION F2: NON-CRUSH FEED WITH SERVO MOTOR, TOP VACUUM TRANSFER

|

NO |

Position Design |

Description |

Remark |

|

1 |

Non Crush Feeder Table |

4 sets of servo-motors in order to achieve non-crush results. |

|

|

Extended vacuum transfer table. |

|

||

|

Continue feed/Single feed/Skip feed |

|

||

|

2 |

Air suction |

Suction intensity controlled by inverter |

|

|

Air volume adjustable to suit different size sheets |

By manual |

||

|

3 |

Side guide |

Computerized setting, position with memory storage |

|

|

Automatic side-squarer plate |

|

||

|

4 |

Front guide |

Descending/ascending by motorized |

option |

|

Left/right moving by motorized |

|

||

|

5 |

Back stop |

Forward/backward by motorized |

|

|

Descending/ascending by motorized |

|

||

|

6 |

Dust removal system/Top Vacuum transfer |

Integrated top suction-case duster |

|

|

Fully vacuum transfer on the top side. |

|

||

|

The pressure adjustable by computerized, Range 0-11MM |

|

||

|

7 |

Gear lubrication |

Oil circuit balancer to connect each section. |

|

|

One lubrication oil pump for gear |

|

||

|

8 |

Main motor |

Frequency inverter control |

|

|

Delay-start safety protection |

|

||

|

The machine cannot start when it is unlocked |

|

||

|

9 |

Alarm buzzer |

It sounds when units opening and closing,and improper operation |

|

|

10 |

Auto zero function |

Zero position return |

|

Printing unit - Top Print/Vacuum transfer

|

NO |

Position Design |

Description |

Remark |

|

1 |

Sheet transfer |

Fully vacuum transfer |

|

|

Transfer wheels are made of cast-aluminum coated with ceramic. |

|

||

|

One side belt with gear transmission |

|

||

|

Grease injection nozzle for each bearing, where there is a transfer wheel. |

|

||

|

Up & down lifting by motorized synchronously, range 0-11MM. |

|

||

|

Suction intensity controlled by inverter |

|

||

|

Air volume adjustable to suit different size sheets |

By pneumatic |

||

|

Gap of sheet transfer case is computerized, range 0-11MM |

|

||

|

2 |

Printing cylinder |

Plate-hanging design: 3x10MM hanging-bar, Depth 12MM*Width 6-8MM. |

|

|

1 plate-hanging slot. And 2 slots as per customer’s request. |

|

||

|

Both sides plate locking bar with single clutch. |

|

||

|

Rotating by foot switch |

|

||

|

3 |

Inking rubber roller |

Made of seamless steel pipe, coated with wear-resisting rubber,dynamic and static balance correction |

|

|

Gap between rubber roller and anilox roller is motorized, Range 0-6MM. |

|

||

|

Quick replacement design |

|

||

|

Ink supply: Double-way pneumatic diaphragm ink pump |

|

||

|

4 |

Chambered doctor blade system |

Chambered design, double doctor-blade |

|

|

With high-pressure washing system, quick washing time and save water |

|

||

|

The ink-return cavity is sprayed with "Teflon"-free layer to avoid ink congestion. |

|

||

|

Nylon scrapper Size: 30M/P3.2/38/45° |

|

||

|

Ink supply: double-way pneumatic diaphragm ink pump |

|

||

|

5 |

Steel anilox roller |

LPI range 180-280 |

|

|

Dot made by mechanically extruded |

|

||

|

Quick replacement design |

|

||

|

6 |

Ceramic anilox roller |

LPI range 28-750 |

|

|

Surface is sprayed with ceramic and dot is by laser engraved |

|

||

|

Open stream mesh arrangement, Excellent ink transfer, saving cleaning time and water consumption |

|

||

|

Good ink transmission, saving cleaning time and water consumption |

|

||

|

Quick replacement design |

|

||

|

7 |

Printing register |

Planetary gear structure 360ºprecisely adjustable, controlled by servo motor |

|

|

Register automatically returns to the original position when units closed after cleaning printing-plate or register changed. |

|

||

|

Zero position button on the touch screen for quick-change printing-plate. |

|

||

|

8 |

Printing Axial move |

Printing cylinder left & right move is motorized, range ± 5MM |

|

|

9 |

Safety button |

When mounting the printing plate (avoids personnel safety hazard caused by mounting printing plate). |

|

|

10 |

Noise silencer/Air channel |

Centralized air channel inside coated with noise-absorbing cotton |

|

|

11 |

Printing Auxiliary Materials |

R-BAK:THK 3.05MM, 1200x2420MM |

Prepare by customers |

|

Plastic film + Printing Plate + R-BAK total 7.2MM THK |

Prepare by customers |

||

|

Printing Plate attached with plastic film Plastic film 0.175MM THK PVC hang bar 3MM THK*W10MM

|

Prepare by customers |

||

|

Printing plate 3.94MM THK |

Prepare by customers |

||

|

12 |

Varnishing unit |

For high-definition printing varnish, improve the glossiness of the carton surface, and at the same time have waterproof function |

Optional |

|

13 |

Little IR dry-well |

For high-definition printing, it can relatively provide ink fast and high speed, and improve production speed |

Optional |

|

14 |

Coding equipment |

According to customer needs, one code per box, easy to identify and manage |

Optional |

Slotting Unit - One unit

|

NO |

Position Design |

Description |

Remark |

|

1 |

Pre-creaser |

4 pairs of pre-creaser wheels (Bottom creasing-line) |

|

|

Half-circle design for easy disassembly |

|

||

|

The gap of creasing rollers is computerized; range 0-11MM. |

|

||

|

2 |

Creaser |

Dual creaser: rough creaser and sharp creaser |

|

|

Creasing Upper/Lower shafts are made of solid steel pipe with precisely grinding, surface chrome plating and balance correcting, equipped with 4 pairs of sharp creasing wheels (Bottom creasing-line) |

|

||

|

Upper Creasing wheels are coated with PU rubber, half-circle design for easy disassembly. |

|

||

|

The gap of creasing rollers is computerized; range 0-11MM. |

|

||

|

3 |

Slotter |

Single-shaft slotting knife design |

|

|

Central knife movable |

|

||

|

The gap of slotting rollers is computerized; range 0-11MM. |

|

||

|

4 |

Linkage plate |

Left & right move on the precise screw shaft with slider. |

|

|

Top & bottom pre-creasing wheels, creasing wheels and knife holders move synchronously along with 4 pieces sliders |

|

||

|

Linkage plates are controlled by computerized with balancer at the both side |

|

||

|

5 |

Slotting knife holder |

The box-heigh is synchronously adjusted on the knife holders |

|

|

“HUG” design to reach smaller slotting space |

|

||

|

Copper blocks with self-lubrication, two side exchangeable. |

|

||

|

Dust removal block for upper slotting knife holder |

|

||

|

6 |

Corner cutter |

Spring type corner cutter holder, easy replacement. |

|

|

Corner knife L47 x H30 x THK10 MM for Three layer of sheet. L47 x H26 x THK10 MM for Five layer of sheet. |

|

||

|

Bottom slotting anvil for corner cutter 50MM THK. |

|

||

|

7 |

Upper slotting knife/trimming knife |

Alloy steel, heat treatment and precisely ground, and the hardness is HRC60-63 |

|

|

8 |

Slotting register |

Planetary gear structure 360ºprecisely adjustable, controlled by servo motor |

|

|

Register automatically returns to the original position when units closed after cleaning printing-plate or register changed. |

|

||

|

Register fixed controlled by pneumatic with brake |

|

||

|

When the units are opening or adjusting register, brake structure stop the machine running. So that keeps the front knife’s position |

|

||

|

Register adjustment for slotting axial/phase/box height is computerized |

|

||

|

9 |

Slotting Axial move |

Slotting shaft left & right move is motorized, range ± 5MM |

|

|

10 |

Waste conveyor belt |

To remove the waste paper fall from slotting and trimming knife. |

|

|

11 |

Safety button |

When mounting the printing plate (avoids personnel safety hazard caused by mounting printing plate). |

|

Die-cutting Unit - One unit

Option one: die cutter with standard model

Option two : die cutter with slotter attachment manual adjustment

Option three : die cutter with slotter attachment with motorized

|

NO |

Position Design |

Description |

Remark |

|

1 |

Die-cutting cylinder |

Bottom Roll |

|

|

Made of seamless steel pipe, forging head is entangling by heat sleeve process, shaft-locking structure, dynamic and static balance adjustment, hard chrome-plating and precision grinding. |

|

||

|

Hole distance vertical 100MM, horizontal 20 division, M10 screw. |

|

||

|

Standard wooden die height 25.4 MM for easy making and fast installation. |

|

||

|

2 |

Die cutting register |

Planetary gear structure 360ºprecisely adjustable, controlled by servo motor |

|

|

Register fixed controlled by pneumatic with brake |

|

||

|

3 |

Die cutting Axial move |

Die cutting shaft left & right move is motorized, range ± 5MM |

|

|

4 |

PU anvil roller |

Top Roll |

|

|

Anvil Roller Eccentric Gear and Wall are equipped with Special Steel Sleeve, and Shaft Heads are equipped with Rack-type Cylinder bottom-fixing Device, which greatly increases the service life of Eccentric Gears and stability of the Anvil Cylinder. |

|

||

|

The gap of die-cutting anvil is computerized; range 0-13MM. |

|

||

|

Vertical swimming structure to move the anvil roller left & right, range ± 30MM |

|

||

|

5 |

Line speed compensation |

Standard: Controlled by mechinical clutch |

|

|

1: bottom roller are driven by two independent servo-motors |

Optional |

||

|

6 |

Paper guide roll |

2/3 pcs guiding wheels, controlled by manual |

|

|

The gap of guide roll is computerized, range is 0-30MM. |

|

||

|

7 |

Waste conveyor belt |

To remove the waste paper fall from die cutting cutter. |

|

|

8 |

Safety button |

When mounting the printing plate (avoids personnel safety hazard caused by mounting printing plate). |

|

|

9 |

Auxiliary Materials |

Thickness of PU 8 MM, W250MM. |

|

INLINE FOLDER GLUER

|

NO |

Position Design |

Description |

Remark |

|

1 |

Fold mode |

Down-fold, to cooperate with top-print Flexo |

|

|

Option 1: KEQI auto gluing system with nozzle |

|

||

|

Option 2: USA Valco auto gluing system with nozzle |

option |

||

|

3 |

Servo controller |

Left & right fold wheels controlled by servo-motor |

2 sets |

|

Left &right fold belts controlled by servo-motor |

2 sets |

||

|

Bottom driving belts controlled by inverter |

1 set |

||

|

Fold pully support rods are controlled by servo-motor |

2 sets |

||

|

Top holding arm forward/backward/up/down controlled by servo-motors |

2 sets |

||

|

Top press arm is controlled by servo motor |

1 set |

||

|

Bottom holding pallet up/down controlled by servo-motor |

1 set |

||

|

Eject belts are controlled by servo-motor |

1 set |

||

|

Paper input lower belt servo motor |

1 set |

||

|

4 |

Paper receiving entrance |

The Right & Left Belt pressure, angle can be adjusted, to ensure the carton can be conveyed synchronously and smoothly |

|

|

Upper and bottom brushers, Blower to avoid the straps into folder section. |

|

||

|

5

|

Main drive belt |

Driven by main motor |

|

|

The main conveying belt is equipped with suction holes, so that the suction can absorb the cardboard through the holes |

|

||

|

6 |

Left & right beam |

Fixed at linear guide rails, move along with sliders |

|

|

Left & right move automatically by computerized. |

|

||

|

7 |

Fold-wheels |

By gear transmission |

|

|

The wheels can be micro-adjusted to ensure folding accuracy, and reduce big gap & small gap, fish tail. |

|

||

|

Run synchronously with main drive belts |

|

||

|

8 |

Fold-belts |

Run synchronously with main drive belts, also can run independently to adjust the speed difference, to ensure different size of carton to be folding more accuracy |

|

|

9 |

Suction conveyor |

The rear section of folder quipped with auxiliary suction motor to ensure cardboard convey straightly. |

|

|

10 |

Paper-pressing blower |

Exit section is equipped with blower to ensure the cardboard falling smoothly |

|

|

Air intensity controlled by inverter |

|

||

|

Air volume adjustable to suit different size sheets |

|

||

|

11 |

Front squaring-plate |

with automatic squaring device, the speed increase & decrease is followed with main machine speed, to control and reduce fish tail. |

|

|

12 |

Top-load type Counter ejector |

Quantity counting and cartons falling temporary storage stacker from top-height. |

|

|

13 |

Top holding arm |

Top holding arm forward/backward/up/down controlled by servo-motors |

|

|

14 |

Little holding arm |

Little holding arm forward/backward controlled by servo motor, to ensure piles of carton fall evenly |

|

|

15 |

Bottom holding pallet |

Bottom holding pallet down controlled by servo-motor, to cooperate with eject belts and smoothly conveying. |

|

|

16 |

Eject belts |

Controlled by servo-motor |

|

|

Can cooperate with auto strapping machine |

|

DIAMETER OF THE CYLINDER (MM)

|

NAME |

0920 |

1224 |

1428 |

1628 |

|

Printing cylinder |

Ф292/Ф304 |

Ф406/Ф420 |

Ф466/480 |

Ф521.6/Ф536 |

|

Creasing shaft |

Ф110 |

Ф120 |

Ф120 |

Ф148 |

|

Slotting shaft |

Ф124 |

Ф170 |

Ф164 |

Ф164 |

|

Die-cutting Cylinder Diameter |

Ф255.2/Ф306 |

Ф371.2/Ф422 |

Ф431.2/482 |

Ф487/Ф537.8 |

|

PU Anvil roller |

Ф267/Ф283 |

Ф388.9/Ф404.9 |

Ф389/480 |

Ф388.9/Ф404.9 |

DIMENSIONS & WEIGHT OF EACH UNITS

|

NAME |

0920 |

0924 |

1224 |

1428 |

||||

|

MM |

KG |

MM |

KG |

MM |

KG |

MM |

KG |

|

|

Feeder unit |

5150x1950x2400 |

5400 |

5450x1500x2600 |

5900 |

5500x1500x2600 |

6450 |

5750x1800x2700 |

7000 |

|

Printer Unit |

5150x700x2400 |

4200 |

5450x780x2600 |

4500 |

5500x780x2600 |

4770 |

5750x700x2700 |

5600 |

|

Slotter unit |

5150x1400x2400 |

7800 |

5450x1400x2600 |

8800 |

5500x1430x2600 |

10000 |

5750x1500x2700 |

11300 |

|

Die cutter unit |

5150x900x2400 |

4250 |

5450x900x2600 |

4850 |

5500x900x2600 |

5800 |

5750x1050x2700 |

7100 |

|

Central Console |

850x500x1000 |

60 |

850x500x1000 |

60 |

850x500x1000 |

60 |

850x500x1000 |

60 |

|

Folder Gluer |

|

|

12100x4671x3200 |

|

|

|

|

|

MOTOR

|

FEEDER UNIT |

Brand |

Quantity |

|

Main motor |

QUFU |

1 |

|

**Feeding servo motors |

ABB |

4 |

|

Suction motor |

GAOBEIDIAN, CHINA |

1 |

|

Top suction motor (dust removal) |

YINGFA, CHINA |

3/4 |

|

Front guide up & down |

SANKAI.CHINA |

1 |

|

Left & right guide move |

SANKAI.CHINA |

2 |

|

Back stopper up & down, forward/backward |

SANKAI.CHINA |

2 |

|

units move |

CPG.TAIWAN |

1 |

|

PRINTER UNIT |

Brand |

Quantity |

|

Vacuum transfer case gap adjusting motor |

SANKAI ,CHINA |

1 |

|

Rubber roller rotating motor |

CPG.TAIWAN |

1 |

|

Anilox roller gap adjusting motor |

SANKAI ,CHINA |

1 |

|

Vacuum transfer case suction motor |

SANKAI,CHINA |

1 |

|

Register servo motor |

INNOVANCE CHINA |

1 |

|

Printing cylinder lateral moving motor |

SANKAI.CHINA |

1 |

|

SLOTTER UNIT |

Brand |

Quantity |

|

Register by servo motor |

INNOVANCE CHINA |

1 |

|

Box-height adjusting motor |

SANKAI.CHINA |

1 |

|

Pre-creaser gap adjusting motor |

SANKAI.CHINA |

1 |

|

Creaser gap adjusting motor |

SANKAI.CHINA |

1 |

|

Slotter gap adjusting motor |

SANKAI.CHINA |

1 |

|

Linkage plate position adjusting motor |

SANKAI.CHINA |

5 |

|

DIE CUTTER UNIT |

Brand |

Quantity |

|

Register by servo motor |

INNOVANCE CHINA |

1 |

|

Die drum gap adjusting motor |

SANKAI.CHINA |

1 |

|

Die drum lateral moving motor |

SANKAI.CHINA |

1 |

|

Anvil roll line speed compensation |

SANKAI.CHINA |

1 |

|

**Anvil roll line speed compensation servo |

VECTOR |

1 |

|

Pull roll gap adjusting motor |

DONGYU, TAIWAN |

1 |

|

Scraps removal |

SANKAI.CHINA |

1 |

|

VIBRATOR CLEANER |

Brand |

Quantity |

|

Main motor |

YINGYI |

1 |

|

Vibrating shaft rotating motor |

FENGHENG |

2 |

|

Scraps removal |

YINGYI |

1 |

|

Blower |

HOYAGM |

5 |

|

AUTO STACKER |

Brand |

Quantity |

|

Main motor |

YINGYI |

1 |

|

Stacking basket up and down |

TUCCSEN |

1 |

|

INLINE FOLDER GLUER |

Brand |

Quantity |

|

Main motor |

DONGYUAN CHINA |

1 |

|

Bottom driving belt servo motor |

CT ENGLAND |

1 |

|

Fold-wheels servo motor |

CT ENGLAND |

2 |

|

Fold-belts servo motor |

CT ENGLAND |

2 |

|

Belt wheel holding rod servo motor |

CT ENGLAND |

2 |

|

Upper paper holding arm back&forth, up&down servo motor |

CT ENGLAND |

2 |

|

Paper press rack up&down servo motor |

CT ENGLAND |

1 |

|

Lower paper holding rack up&down servo motor |

CT ENGLAND |

1 |

|

Discharge belt servo motor |

CT ENGLAND |

1 |

|

Paper input lower belt servo motor |

CT ENGLAND |

1 |

|

Folder suction blower |

POPULA CHINA |

2 |

|

Paper output press blower |

POPULA CHINA |

1 |

|

Left/right arm moving motor |

CPG, TAIWAN |

1 |

|

Paper output clapping motor |

CPG, TAIWAN |

1 |

|

Paper output transverse motor |

CPG, TAIWAN |

1 |

|

Paper press rack up&down, back&forth motors |

CPG, TAIWAN |

2 |

|

Paper output guiding gap motor |

CPG, TAIWAN |

1 |

BELT LIST

|

Name |

Model |

QTY. |

Unit |

Unit price |

Amount |

||||

|

FEEDER UNIT |

|||||||||

|

Timing Belt for driving vacuum box shaft |

8M*600-T75*55W |

4 |

pcs |

|

|

||||

|

Timing Belt for driving vacuum box shaft |

8M*960-T120*50W |

4 |

pcs |

|

|

||||

|

Timing belt for driving top vacuum box shaft |

8M*1464-T183*50W |

1 |

pcs |

|

|

||||

|

Main motor Belt |

14M*2156-T154*120W |

1 |

pcs |

|

|

||||

|

Timing belt for adjusting the gap of top vacuum box |

5M*455-T91*25W |

1 |

pcs |

|

|

||||

|

PRINTER UNIT |

|||||||||

|

Timing belt for Vacuum box shaft |

8M*1680-T210*50W |

3 |

pcs |

|

|

||||

|

Timing belt for driving anilox roller |

330H-T66*50W |

3 |

pcs |

|

|

||||

|

Timing belt for driving rubber roller |

330H-T66*50W |

3 |

Pcs |

|

|

||||

|

SLOTTER UNIT |

|||||||||

|

Timing belt for driving screw shafts |

8M*520-*T65*35W |

5 |

pcs |

|

|

||||

|

DIE CUTTER UNIT |

|||||||||

|

Belt of PU anvil roll |

1790x100x4 |

1 |

Pc |

|

|

||||

|

Waste paper conveyor belt |

2710*1510*2MM |

1 |

Pc |

|

|

||||

|

VIBRATOR STACKER |

|||||||||

|

Elastic Belt |

|

|

pcs |

|

|

||||

|

Vibrator Receiving belt |

2800*70 MM |

|

pcs |

|

|

||||

|

Stacker Receiving belt |

2800*70 MM |

|

pcs |

|

|

||||

|

Conveyor belt |

10000*70 MM |

|

pcs |

|

|

||||

|

INLINE FOLDER GLUER |

|||||||||

|

Timing belt for driving bottom shaft |

1016*M8*50W |

1 |

pcs |

|

|

||||

|

Main motor Belt |

V-belt B-1900 |

4 |

pcs |

|

|

||||

|

Top conveyor belt with holes |

17130*90*8MM |

2 |

Pcs |

|

|

||||

|

Bottom conveyor flat belt |

8700x90x6MM |

2 |

Pcs |

|

|

||||

|

Left Up-fold belt |

9300x90x6MM |

1 |

Pc |

|

|

||||

|

Right Up-fold belt |

8815x90x6MM |

1 |

Pc |

|

|

||||

|

Conveyor belt (buckle) |

6760*60*5MM |

6 |

pcs |

|

|

||||

TOOL LIST AND SPARE PART LIST

|

NAME |

SPEC. |

QTY. |

|

Complimentary Tools |

||

|

Hexagon spanner |

|

1 set |

|

Open end spanner |

12# 13# 14# 16# 17# 18# 19# 22# 24# |

1 pc for each spec. |

|

Screw driver |

Cross, slotted |

1 pc for each spec. |

|

Oil bottle |

|

1 pc |

|

Pneumatic Grease Gun |

|

1 pc |

|

Monkey wrench |

10# |

1 pc |

|

Needle nose plier |

|

1 pc |

|

Wrench for hanging plate |

|

1 pc |

|

Tool kit |

|

1 pc |

|

Instruction manual |

|

|

|

Complimentary Spare Parts |

||

|

Ratchet and pawl |

|

4 sets |

|

Corner cutter base |

|

2 pcs |

|

Corner cutter knife |

|

5 pcs |

|

Corner cutter spring |

|

Several |

|

Pump chips |

|

5 pcs |

|

air pipe joint |

|

Several |

|

Feeder rubber wheel |

Circle in one piece |

6 pcs |

|

Solenoid valve |

|

2 pcs |

|

Screws |

|

Several |

|

Proximity switch |

|

2 pcs |

|

Photoelectric switch |

|

1 pc |

|

Brake block |

|

1 pc |

|

Expansion screw |

14x150 |

100 pcs |

|

Air pipe |

M16 |

3 meters |

|

Encoder |

|

1 pc |

|

Oil Pump |

Standard |

1 pc |

|

Ink Pump |

|

2 sets |

|

Timing belt for feeder |

600-75T-55W-8M |

2 pcs |

|

Timing belt for feeder |

960-120T-50W-8M |

1 pc |

|

Time belt for printer |

1680-120T-50W-8M |

4 pcs |

|

Belt for rubber roll |

330H-66T-50W |

2 pcs |

|

Belt for slotter moving |

520-65T-35W-8M |

2 pcs |

MAIN PARTS & BRAND

|

NO |

Name of commodity |

Brand |

Origin of place |

|

1. |

Inking rubber roller |

JINGYANG |

DONGGUAN,CHINA |

|

2. |

Chambered doctor blade system |

KEROU |

GUANGDONG,CHINA |

|

3. |

Ceramic anilox roller |

YUEXIN |

CHINA |

|

4. |

Main Inverter |

ABB |

SWITZERLAND |

|

5. |

PLC |

DELTA |

TAIWAN |

|

6. |

Touch screen |

DETAL |

TAIWAN |

|

7. |

Pneumatic control, such as Air cylinder/Solenoid valve |

AIRTAC |

CHINA |

|

8. |

Proximity switch |

OMRON |

JAPAN |

|

9. |

Photoelectric switch |

OMRON |

JAPAN |

|

10. |

Rotary Encoder |

KOYO |

JAPAN |

|

11. |

Low-voltage electronic components such as air-break, contactor and relay |

SCHEEIDER OR SIEMENS |

CHINA |

|

12. |

Main Bearings, Such as for printing drum shaft, anilox roll shaft… |

NSK |

JAPAN |

|

13. |

Expansion sleeve |

XIANYANG |

CHINA |

|

14. |

Diaphragm pump |

CHANGJIANG |

CHINA |

|

15. |

Dual-way Diaphragm pump |

ARO |

AMERICA |

|

16. |

Slotting knife |

QIFENG |

CHINA |

|

17. |

PU Anvil cover |

POLY CART |

ITALY |

Without affecting the performance of the machine, the seller reserves the right to choose the brand (same level brand or much better brand) without notice!!!

Shape and size for reference.

Previous:

Next:

INQUIRY