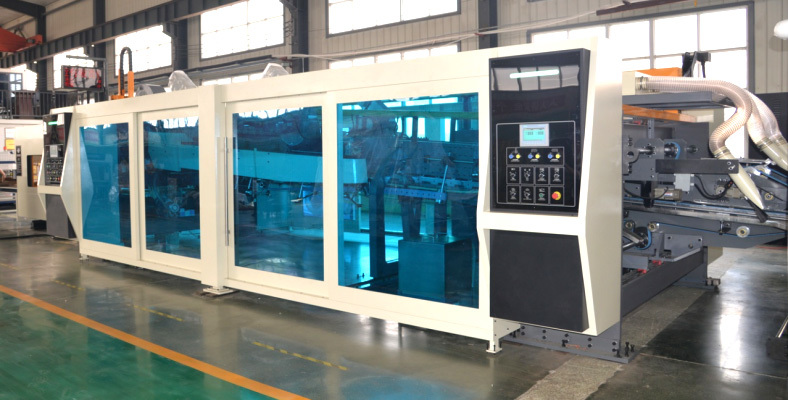

XT-S Model FFG Inline machine

Feeder Unit: Pressure-Free leading edge paper feeding device, Accurate pressure-free paper feeding、 Regular side beat

Views:

1000

Keywords

Details

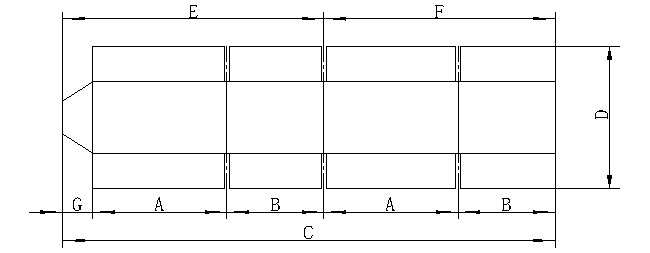

Attachment:Illustration of machine units

Product Details: Flexo Folder Gluer

Main Technical parameters

|

Item |

Unit |

Style |

|

Top Speed |

mm |

300 rpm |

|

Max. Sheet Size |

mm |

1270×2500 |

|

Max. Printing Size |

mm |

1200×2400 |

|

Skip Feed Size |

mm |

1450×2400 |

|

Min.Board Width |

mm |

320 |

|

Thickness of Printing Plate |

mm |

7.2 |

|

Printing Precision |

mm |

4colors±0.5 |

|

Slotting Precision |

mm |

± 1.5 |

|

Min. Slotting Interval |

mm |

280X80X280X80 |

1、Feeder Unit:

Pressure-Free leading edge paper feeding device

Accurate pressure-free paper feeding、 Regular side beat

Independent adsorption transfer box

Multi-exclusion of electrostatic brush、 enhanced suction dust removal system

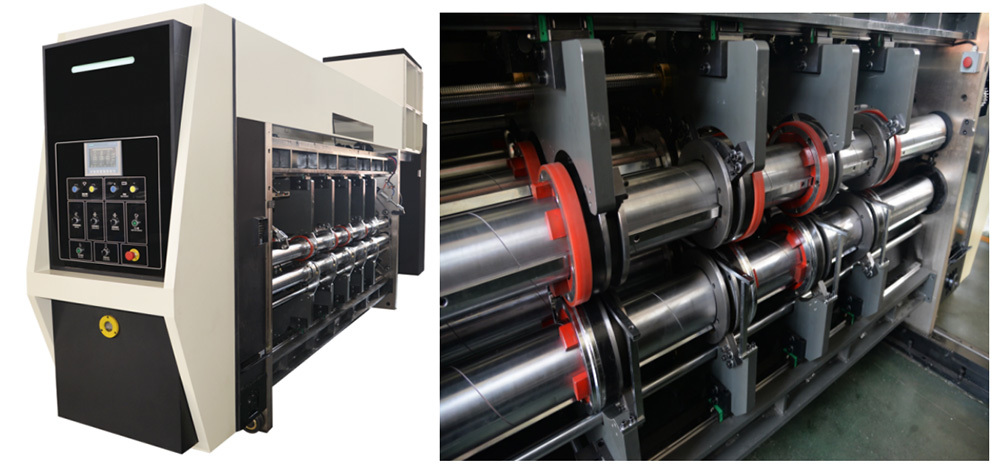

2、Printing Unit:

On-india vacuum adsorption transfer

Four groups of ceramic rollers with scraper system

Anilox roller quick replacement system

Ink-saving circulation rapid cleaning system

3、Forming Unit:

“Enhanced” multi-indentation molding

Large damage wheel, pre-pressing wheel、 Large pressure line wheel forming system

Precision linear guide rail linkage system

4、Slotting Unit:

“Single seat” front and rear knife coaxial type

Double Line roller system、Middle knife movable type

Precision linear guide rail linkage system

5、Die-cutting Unit:

Differential compensation system

Reinforced rubber pad grinding system

6、Scrapping Unit:

“Unit type” waste disposal structure

The paper connecting arm and the upper pressing wheel computer adjust the transverse moving system

Vacuum adsorption belt transmission, guide wheel auxiliary system

Hair Drye、 brush、high-pressure hair dryer、brush cleaning system

7、Folding and gluing box machine

(1)Paper feed paste Unit:

Up and down belt gripping transmission

Adjustable rubber coating box

Multi-duct dust blowing system

The gap of feed guide pulley is electrically controlled

(2)Folding Unit:

“Down folding” beam folding box, vacuum adsorption assistance

High-strength beam, precision linear guide rail transversal system

Intermediate support, precision linear guide rail system

Elastic Guide roller system, pneumatic clearance control

The belt is shaped on both sides, and the belt is transmitted and controlled by frequency conversion

Folding and shaping guide pulley, segmented adjustment system

Two-side adsorption belt rectification system

(3)Stack counting unit:

“Up and down” collection

Multi-servo drive, high-speed collection system

Tidy up the box, high-speed counting collection

Conveyor platform servo control belt transmission

Transverse electric displacement of the output part

COMPUTER CONTROL SYSTEM

|

NO |

Position Design |

Description |

Remark |

|

1 |

HIM |

Integrated computer communicates with each section. |

|

|

Order setting up, save and recall |

|

||

|

Order number input, such as ABC123, max order quantity 3000 |

|

||

|

Date calibration/correction. |

|

||

|

Alarm tele-communication fault and reset. |

|

||

|

2 |

Functional buttons |

Manually control with buttons available. |

|

|

3 |

Remote controller |

Remote control to debug the failures |

|

Feeding Unit

|

NO |

Position Design |

Description |

Remark |

|

1 |

Machine clutch |

The electric control machine is equipped with clutch alarm and continuous alarm to ensure the safety of workers. |

|

|

Drive shaft with friction clutch to avoid misoperation and harm the machine. |

|

||

|

Air-pressure interlock device ensures stable operation of the machine. |

|

||

|

Main motor adopts frequency conversion motor, frequency conversion control, energy saving, smooth start, with motor start protection device. |

|

||

|

2 |

New servo leading edgefeeding system (exclusive patent product) |

Suction auxiliary paper feed, fan 11kw, using frequency conversion control, according to the different conditions of paperboard bending, air volume adjustment to ensure smooth paper supply. |

|

|

The machine is equipped with a chain control switch at the end to control the emergency stop paper feeding. |

By manual |

||

|

The paper feeding system with new servo leading edge roller can greatly improve the pressure resistance of processed paperboard. |

|

||

|

The front baffle clearance adopts servo adjustment, the clearance is accurate. |

|

||

|

The position of side baffle is adjusted by electric and numerical setting, and the limit value and limit switch are set by program. |

|

||

|

The side baffle is mounted on the operation side, driven by air pressure, and the extrusion frequency can be set by time. |

|

||

|

The position of the rear gearbox is adjusted according to the width of paperboard, electric and numerical settings. The limit value is programmed and the limit switch is double protective device. The height of rear gearbox is adjusted by electric motor. Equipped with roller layer device to reduce the weight of the upper paperboard backlog. Equipped with auxiliary back-up roller to prevent sagging of wide board. |

|

||

|

Sheet feed device (continuous or sheet feed can be selected according to the need) . |

|

||

|

Paper counter, set up, display the production quantity. |

|

||

|

3 |

Dust removal device |

The upper suction fan is used in the paper feeding part, and the electrostatic brush is installed in the suction port, which can remove the impurities on the printed surface of the paperboard and improve the printing quality. |

|

|

|

|

||

|

4 |

Paper feeding roller |

The outer diameter of upper roller is 144mm. |

option |

|

The upper roller feeding wheel is wrapped with wear-resistant rubber, and the balance is corrected. |

|

||

|

Outer diameter of lower roller 156mm embossing plating hard chromium, and do balance correction. |

|

||

|

The gap of feeding roller is adjusted by servo motor, the adjustment range is 0-12mm, and the limit value is set by program. |

|

||

|

5 |

Automatic return-to-zero device |

Paper feeding section, printing section, slotting section electric automatic zero. |

|

|

General Carton using automatic return to zero device, printing two can be adjusted to the correct position, reduce cardboard waste. |

|

Printing unit - Top Print/Vacuum transfer

|

NO |

Position Design |

Description |

Remark |

|

1 |

Printing Roll (plate roll)

|

The outer diameter is ¢406㎜ |

|

|

Steel tube surface grinding, hard chromium plating |

|

||

|

Do balance correction, running smoothly |

|

||

|

Self-locking friction type reels |

|

||

|

Full version of the slot, suitable for 10mm × 3mm hanging plate. |

|

||

|

Loading and unloading printing plate, foot switch electric control positive and negative |

|

||

|

Wipe version reset function, WIPE version before the computer memory printing position, wipe version after automatic rese |

|

||

|

Version of the roll transverse servo adjustment, adjustment of a total of 10mm |

|

||

|

The phase of printing plate roller is adjusted by servo, so that the position is accurate and the time is saved |

|

||

|

Phase drive gear keyless expansion sleeve connection |

|

||

|

2 |

Printing press roller |

The whole process of vacuum adsorption transfer, paper feed smooth |

|

|

Steel tube surface grinding, hard chromium plating |

|

||

|

Do balance correction, running smoothly |

|

||

|

The press roller gap of printing bellows is servo-adjusted, digital display, adjustment range is 0-12mm, limit value is programmed and limit switch is double protective device |

|

||

|

Special hard ceramic wheel feeding paper, long service life, to ensure the accuracy of cardboard transmission |

|

||

|

The suction pressure valve adopts pneumatic control |

|

||

|

The suction conveyor does not need to install strip printing plate in the non-printing unit to reduce the plate loading time |

|

||

|

3 |

Ceramic Anilox Roller |

The outer diameter is ¢228㎜ |

|

|

Adopt Quick Roll Change System |

|

||

|

With the printing plate roller clearance servo adjustment |

|

||

|

With the paper feeding system pneumatic automatic lifting device. When feeding, the anilox roller drops in contact with the printing plate. When feeding stops, the anilox roller rises and separates from the printing plate |

|

||

|

Anilox roller with wedge-type overrunning clutch, even ink, wash ink when convenient and fast |

|

||

|

Than the steel roller printing fine fine, wear-resistant, long life |

|

||

|

The automatic ink mode stops/starts with the moving paper state, and the ink of each printing unit starts/stops automatically with the moving paper |

|

||

|

4 |

Phase adjustment mechanism |

Planetary gear structure, servo motor adjustment phase. |

|

|

5 |

Ink circulation |

Pneumatic double diaphragm pump, stable ink supply, simple operation and maintenance |

|

|

Ink filter screen, filter impurities |

|||

|

Equipped with rapid cleaning system, saving water consumption |

Forming Unit

|

NO |

Position Design |

Description |

Remark |

|

1 |

“Enhanced” multi-indentation molding, large damage wheel, pre-pressing wheel,large pressure line wheel molding system |

|

|

|

2 |

The precision linear guideway synchronous linkage of multi-pressure line seat adopts servo adjustment, program setting limit value and limit switch double protection device |

|

|

|

3 |

Bobbin: shaft diameter is 164mm, using carbon steel conditioning treatment, surface grinding, hard chromium plating, moving smoothly, enhance rigidity, destructive force |

|

|

|

4 |

The clearance of prepressing line is adjusted by servo, and the limit value and limit device are set by program |

|

|

Slotting Unit - One unit

|

NO |

Position Design |

Description |

Remark |

|

1 |

Linkage knife adjustment |

The synchronous linkage of slotting interval of slotting tool base, pre-pressing wheel and line pressing wheel adopts servo adjustment, limit value is set by program and limit switch is double protective device |

|

|

2 |

Slotted shaft |

Shaft diameter is 164mm, using carbon steel quenching and tempering treatment, surface grinding, hard chromium plating, moving smoothly. The middle knife is movable, and the limited position protection device is installed between each slotted knife base. The gap between slotted cutter head and bottom cutter is servo adjusted, and the limit value and limit device are programmed |

|

|

The width of the slotting cutter is 7mm |

|

||

|

Alloy steel after heat treatment grinding tooth-shaped slotted cutter, hardness and toughness are both good |

|

||

|

Slotting phase adopts planetary gear structure, servo adjustment, accurate positioning and save time, phase transmission gear key-free expansion sleeve connection |

|

||

|

The height of carton is servo adjusted |

|

||

|

3 |

Spool press |

Double pressure line, shaft diameter is¢110mm |

|

|

Creasing wheel clearance Servo adjustment, program set limit value and limit switch double protection device |

|

|

NO |

Position Design |

Description |

Remark |

|

1 |

Tool Die Roll (lower roll) |

The outer diameter is 371.2 mm (without cutter die) and adopts servo independent drive |

|

|

Surface grinding, hard chrome plating, balance correction, increased operational stability |

|

||

|

Die-cutting phase servo adjustment with numerical settings, accurate positioning to save time |

|

||

|

Tool die fixed screw hole spacing 500㎜×500㎜ |

|

||

|

Suitable for tool height 25.4 ㎜ |

|

||

|

Die-cutting knife horizontal adjustment, servo adjustment, control range of 20mm |

|

||

|

The center of the die roller is engraved with the center line, so that the template can be installed conveniently |

|

||

|

Die-cutting knife die roller with thread socket, to prevent damage to the fixed screw hole |

|

||

|

2 |

Rubber pad roll (top roll) |

The outer diameter is¢388.9 ㎜ |

|

|

Surface grinding, hard chromium plating |

|

||

|

Balance correction to increase operational stability |

|

||

|

PAD thickness 8mm (outside diameter 404.9 mm) , width 250mm |

|

||

|

Rubber roller transverse 60mm swimming device |

|

||

|

The gap between Cutter and die roller is adjusted by servo, the limit value is set by program and the limit switch is double protective device |

|

||

|

3 |

Paper feeding roller |

Top and bottom roll: outer diameter is ¢110㎜ thick wall steel pipe, steel paper ring, paper ring using rack positioning quick adjustment. |

|

|

The gap of paper feeding roller is servo adjusted, and the limit value is set by the program |

|

||

|

4 |

Waste paper output |

The lower part of the unit is equipped with a waste paper output device to facilitate the removal of waste |

|

Scrapping Unit

|

NO |

Position Design |

Description |

Remark |

|

1 |

It adopts“Unit type” waste cleaning structure, four groups of paper connecting arm and upper pressing wheel adopt servo to adjust the transverse position, vacuum adsorption type belt transmission and guide wheel auxiliary system |

|

|

|

2 |

The gap of paper guiding wheel is servo adjusted |

|

|

|

3 |

Six pipeline blowing+brush+eight high-pressure blowing nozzles+brush cleaning system |

|

|

|

4 |

Waste paper output |

The unit is equipped with a waste paper output device below for easy cleaning of waste materials |

|

FOLDER GLUER INLINE

|

NO |

Position Design |

Description |

Remark |

|

1 |

Feeder Unit |

The paper inlet adopts two independent motors to adjust the gap between the paper feeding belts, and the gap size is measured by an electronic ruler |

|

|

Upper and lower belts are used for clamping and conveying |

|

||

|

The left and right movement position of the glue wheel is adjusted by a linear slide rail and precision screw electric adjustment |

|

||

|

Independent gluing cylinder, with dedicated copper glue pump used for gluing |

|

||

|

The structure of the glue box is simple and reliable, and it is easy to clean. The gluing wheel is made of stainless steel material, ensuring long-term use. The glue wheel is equipped with a separate power source to ensure that it can continue to operate uniformly during shutdown |

|

||

|

There are multiple blowing ducts at the front end to clean up the waste generated in the box |

|

||

|

2 |

Folding section |

Adopting reinforced and elongated steel beams to ensure operational stability, with a segmented adjustment system |

|

|

The upper conveyor belt of the folding part adopts an elastic pressure roller system, and the pressure rollers are equipped with limit devices and can adjust the gap size between each pressure roller and the lower conveyor belt separately to ensure accurate paper feeding |

|

||

|

The upper conveyor belt of the folding part adopts a pneumatic gap control system, and the middle upper conveyor belt adopts a dual cylinder, with one click setting of gaps for different thicknesses of cardboard |

|

||

|

The rear section of the folding section adopts a vacuum adsorption belt to transport the cardboard forward to prevent the cardboard from slipping and causing a scissor error |

|

||

|

The lower part of the folding part is equipped with an elastic pressure plate device, which automatically adapts to different thicknesses of cardboard |

|

||

|

The rear section of the folding section is equipped with a lower differential belt and a vacuum adsorption device to adsorb the cardboard to prevent slipping. The speed is higher than that of the upper folding belt, and the frictional force of the lower differential belt rubbing forward cancels out the resistance generated by the folding cardboard, minimizing the scissors difference |

|

||

|

The rear section of the folding section is shaped using forming tower wheels throughout the entire process. The front shaping wheel has separate power to adjust the width of the folding line, and the rear shaping wheel also has separate power to further adjust the width of the folding line at the end of the paper output, making the cardboard folding process precise and controllable, ensuring the exquisite shape of the formed cardboard box |

|

||

|

The folding crossbeam is electrically adjusted for left and right movement, with three front and rear screws connected to ensure smooth adjustment |

|

||

|

The main power adopts a variable frequency speed regulation motor, which is synchronized with the printing machine to ensure smooth cardboard transportation |

|

||

|

The main transmission adopts imported synchronous belts, with precise transmission and low noise |

|

||

|

3 |

Stacking and counting department |

Using photoelectric switch counting, five sets of servo motors are linked and controlled to achieve precise counting and stacking output function under high-speed operation, with precise and reliable batching and low impact force |

|

|

The rear panel can be electrically adjusted according to the width of the cardboard |

|

||

|

The mobile components adopt high-performance linear guides, which are stable and reliable |

|

||

|

Equipped with a paper output and pressure device, the height is computer-adjusted according to the thickness of the stacked cardboard boxes to ensure that the output cardboard does not tilt |

|

||

|

The counting department can move left and right as a whole to ensure that the cardboard box always falls in the middle of the machine |

|

||

|

The strong wind pressure device prevents the folded cardboard from curling up, and the wind direction is adjustable to ensure that the formed cardboard boxes are stacked neatly |

|

||

|

The high-frequency shaping and tapping mechanism performs final correction on the folded cardboard box |

|

||

|

The output belt is equipped with a paper pressing auxiliary wheel device above it, and the gap is electrically adjusted |

|

Transmission gear

|

NO |

Position Design |

Description |

Remark |

|

1 |

Main transmission gear |

Material: 20CrMnTi alloy steel, carburized and quenched, ground and processed |

|

|

Six level accuracy, smooth operation, low noise, hardness HRC58-62, long service life, basicaly no wear within 10 years, can achieve long-term printing alignment |

|

||

|

By using keyless connecting rings, the shaft and gear can be seamlessly connected, without any gaps during use with large torque. Installation and maintenance are more convenient, and long-term transmission accuracy can be high to ensure printing alignment |

|

||

|

2 |

Computer Control Department

|

More than 90% of the electrical appliances used in the entire machine are from internationally renowned brands |

|

|

Machine size adjustment: Enter the size of the order directly (or call the original saved order size to the computer), and perform the adjustment. The machine will automatically adjust the size of each part. Can store 999 commonly used orders |

|

||

|

Machine zeroing, erasing memory, and preset function: Printing, slotting, and die-cutting phase zeroing and presetting can make printing, slotting, and die-cutting ink on the first cardboard, adjust the second cardboard in place, and compensate for errors during operation |

|

||

|

Automatic inking function, the first and last cardboard are inked clearly |

|

||

|

CNC horizontal adjustment of slot cutter: The slot cutter automatically combines with the paper feeding baffle, and can be adjusted with or without trimming, automatically adjusting the paper feeding baffle to the appropriate position |

|

||

|

Machine calibration parameter design: Can calibrate benchmark parameters for easy maintenance and debugging |

|

||

|

Automatic protection: Real monitoring and anti-collision knife protection for slot knife lateral and phase; Knife in groove design, during the process of zeroing and automatic adjustment, the knife enters the groove, which can protect the upper and lower knives from smoothly entering the groove after adjustment, and protect the knives |

|

||

|

Unit program design for whole machine printing, slotting, and die-cutting; Ink shortage alarm; Multi point operation control |

|

||

|

Production speed of 60, 80, 100, 120, cruise control |

|

||

|

Unique inter sheet pre feeding function |

|

||

|

The gaps between different parts can be adjusted by inputting numerical values, with an accuracy of 0.1mm |

|

||

|

Each unit's human-machine interface, touch screen operation adjustment |

|

||

|

The ink bucket holder on the operation side of the printing unit is made of stainless steel material, which is convenient for cleaning ink stains |

|

||

|

Each group of transmission gearboxes adopts an automatic balance spray lubrication system to ensure transmission life |

|

Previous:

Next:

INQUIRY